April 2021

Productionsynchronous delivery directly to the assembly line

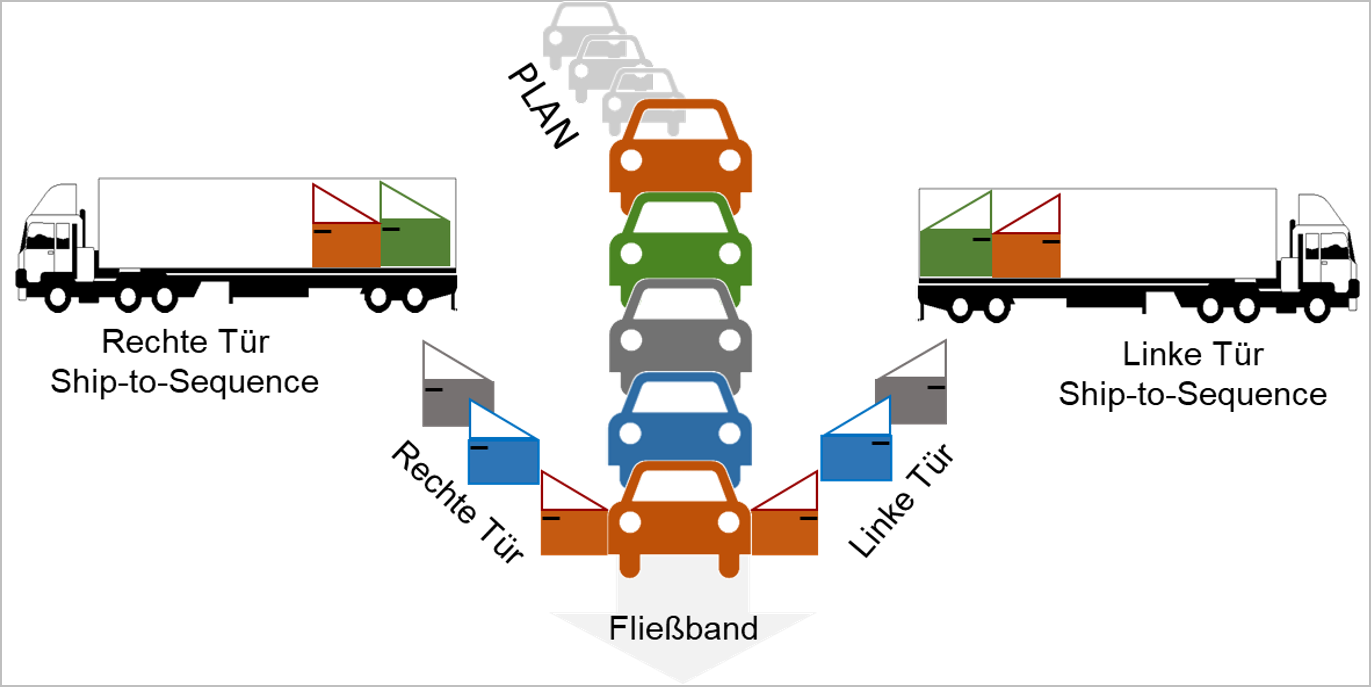

Sequential delivery is a highly automated, sequence-optimized and -synchronous delivery with precise coordination with the production sequence. This means that various variants of the same part or a preconfigured module are delivered to the automobile manufacturer's assembly line at the right time in the right sequence and position.

Call-off integration and sequence scheduling take place automatically via the EDI interface.

SCM not only processes delivery forecast and delivery JIT (Just In Time), but also the productionsynchronous call-offs. The goods are not stored by the customer, but are installed immediately. This means that the goods are transported directly to the customer's point of consumption. Different types of vehicles run on the manufacturer's conveyor belt and packaging can contain different items.

As a rule, they are molded parts that are in the corresponding packaging position in the order of the vehicle types to be produced (e.g. vehicle doors). The parts are removed in a sequence and the sequence is maintained on a pallet across several SLC. Usually, a sequential delivery is also accompanied by special labeling and package contents lists.

Would you like to get in contact or wish further information? vertrieb@apliko.de